With an endless amount of applications and unlimited choice of end effectors, you can always find an industrial manipulator to suit your circumstances. Handling materials from A to Z and everything in between has never been easier. With a wide variety of manipulator mounting options like, pedestal, foundation, column, overhead, overhead rail, mobile base and floor rail, there’s always an answer to, “How can we find room for this”?

With the ability to go over, under, around, behind, in between and inside, there’s always an answer to, “How do we access this”? With functions like lifting, lowering, balancing, rotating, reaching, twisting, turning, tilting and flipping, there’s always an answer to, “How do we handle this”? And with the possibilities for gripping, grabbing, clamping, hooking, forking, supporting, holding, attracting and suctioning, there’s always an answer to, “How do we secure this”?

With almost limitless options, you can find a manipulator to fill every corner of industry. Manipulators are also excellent for hazardous locations, high-temperature situations, and even explosion-proof environments. When you partner your personnel with an industrial manipulator, your production potential can become limitless too.

Some Questions to Determine Which Manipulator is Right for You

This is where Maximum Material Handling’s team can begin to assist you in acquiring the right tool for the job.

- Preferred power source? Air, Hydraulic or Electric.

- Mounting preference? Pedestal, Floor, Column, Overhead, Overhead Rail, Mobile Base, Floor Rail.

- Product being handled? ___________________________________.

- Product weight? ________Lbs., Minimum? ________Lbs., Maximum? ________Lbs.

- Product shape? ______________________________.

- Product physical dimensions? ___________in. X ____________in. X ____________in.

- Cycle’s per hour? ___________.

- Product handled as a single or in bundles? ________________.

- Maximum height product will travel? ______________in.

- Minimum height product will travel? ______________in.

- Products starting height? ______________in.

- Reach required to cover the area? __________ft. _________in.

- Product temperature? ___________min. ___________max.

- Preferred securing type? Vacuum, Magnet, Mechanical, Grip, Support, Insert, Other?

Why Choose Maximum Material Handling?

Our team has the experience and skill to match your application with the performance of a potential manipulator. We have years of wisdom working in the field representing quality manufactures enabling us to make the sometimes-complex decisions and custom designs necessary to complete the task. When your organization is ready for maximum productivity at peak efficiency immersed in supreme security, you’re ready to talk with Maximum Material Handling about your new industrial manipulator.

Maximum Material Handling is a full-service company. We can design your new industrial manipulator, build your new industrial manipulator, install it, service it, inspect it and test it. We can also supply the same services for existing equipment.

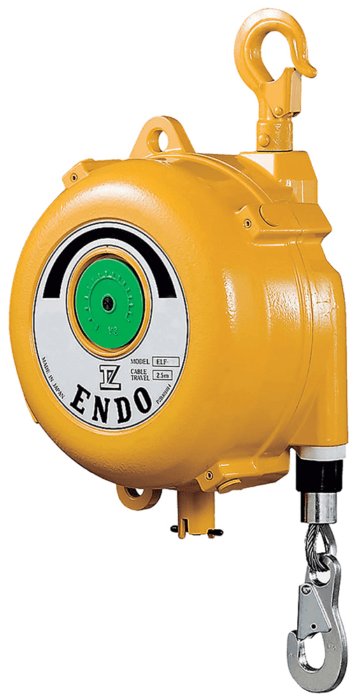

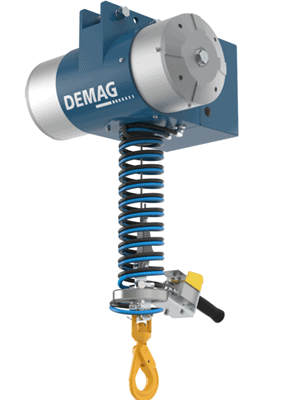

An Overview of Balancers

Unlike a hoist, and at the entry level of an industrial manipulator, a balancer can render the material being handled weightless. Making it effortless for the operator to control the materials lifting and lowering travel. When a balancer is attached to a standard jib crane, articulating jib crane or work station crane this can create a simple but dynamic load control platform, promoting increased productivity, while minimizing operator fatigue.

This combination has seen a dramatic uptick in the proportion of balancers deployed throughout industry in the past decade.