Hoist (Overhead); definition (noun) (as it relates to material handling)

A tool or device constructed with the intended purpose of giving the operator a mechanical advantage in the raising and lowering of heavy material, by means of a chain, wire or fiber rope.

Overview of Hoists

For more than 150 years Industry has looked to the Hoist as the go-to-tool for lifting heavy material. Hoists are the backbone of manufacturing and have found their way into every corner of production across the globe. With their endless application ability, advanced safety features and high efficiency output, you can bet there is a hoist available to suite your needs. Hoists are categorized into three main types, based on their mode of operation, Electric, Manual and Pneumatic (air or gas).

Types of Hoists

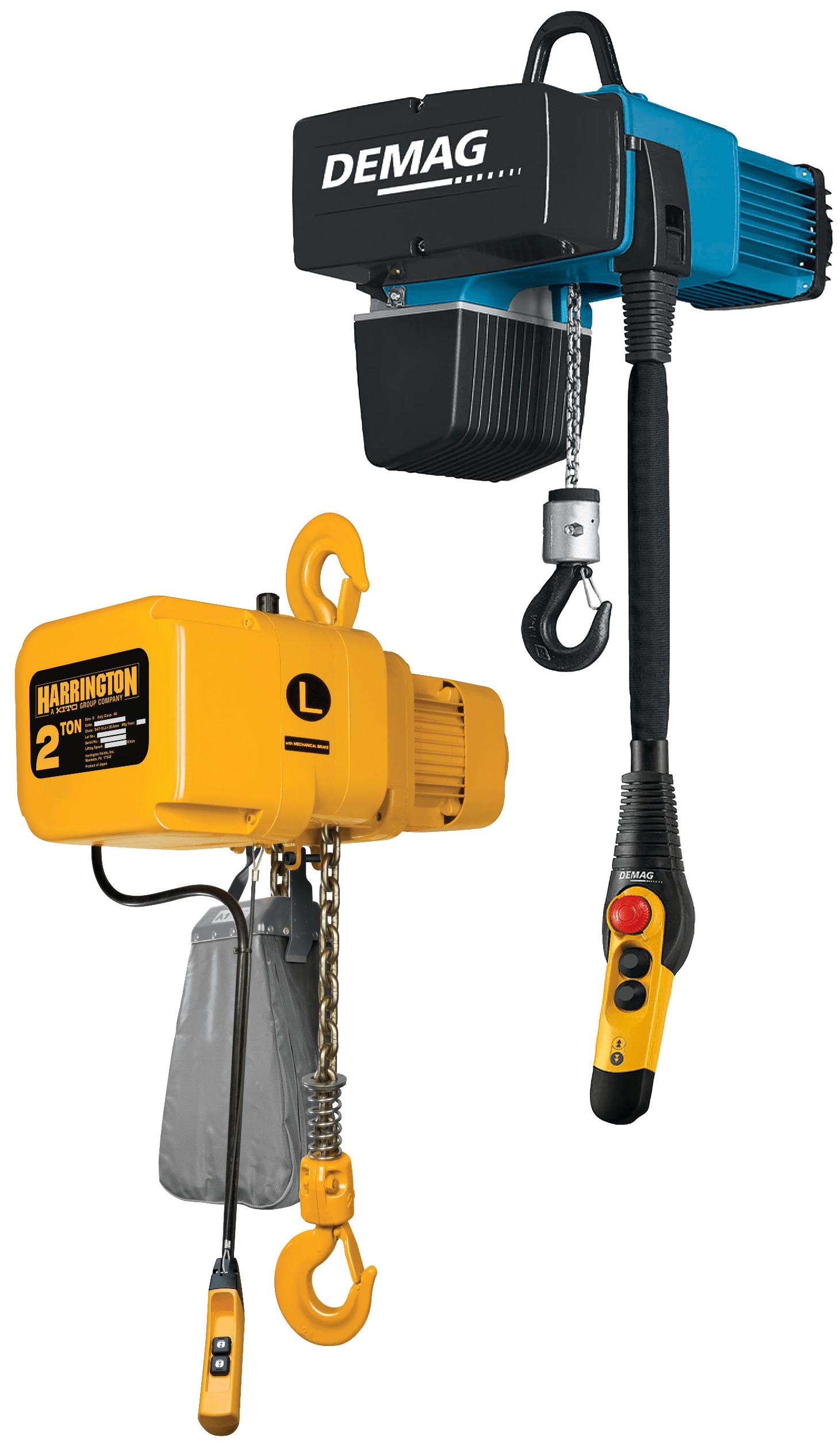

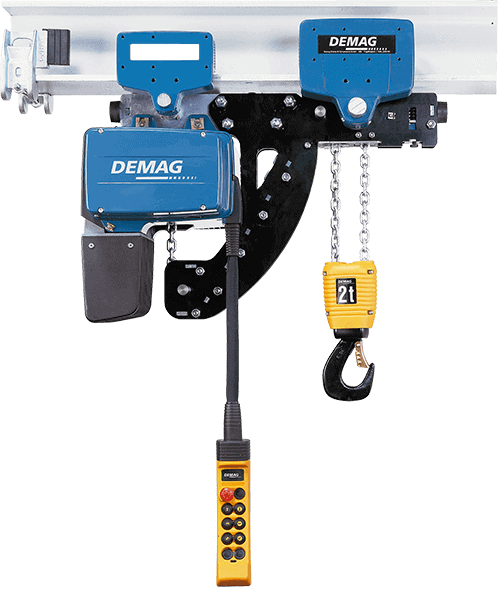

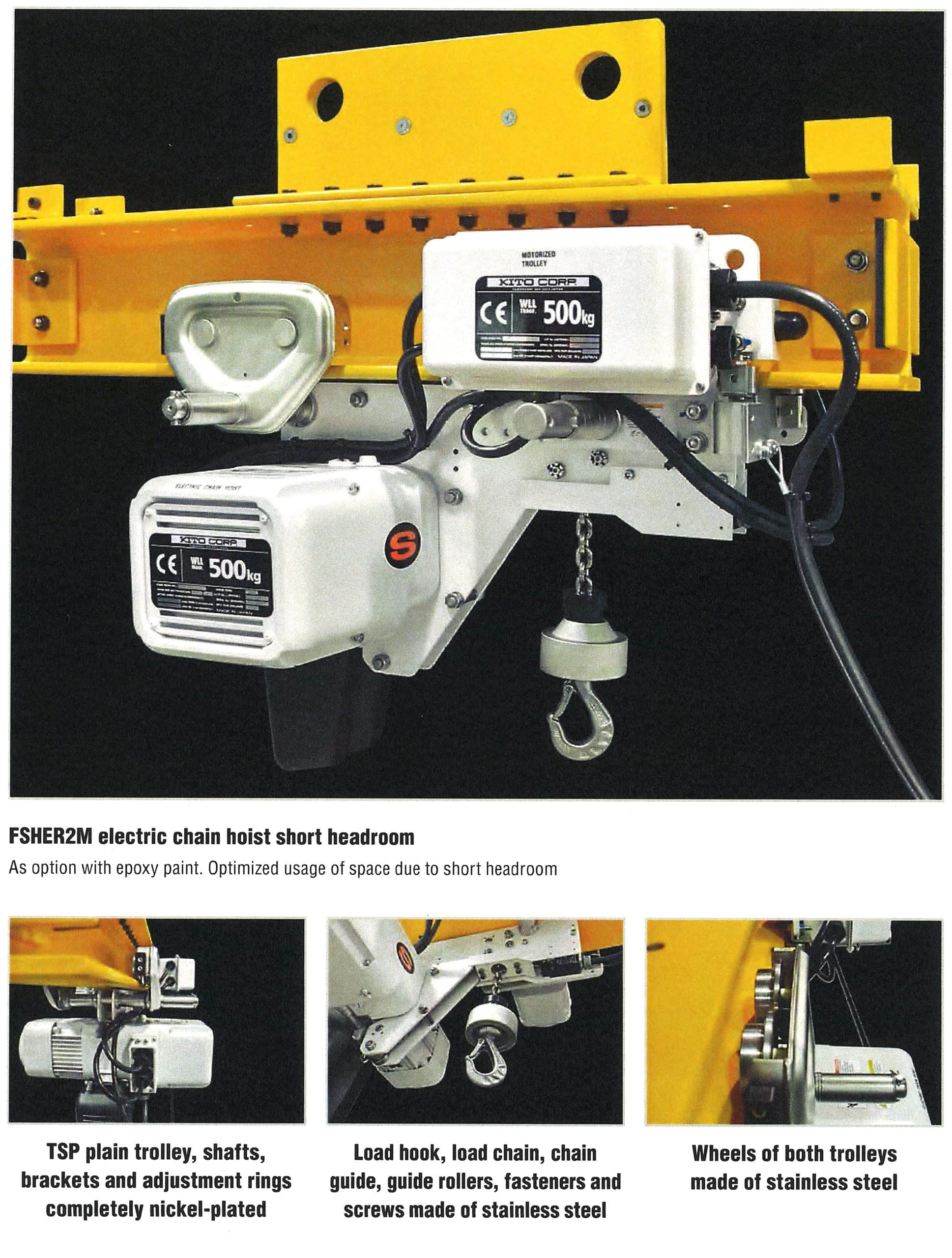

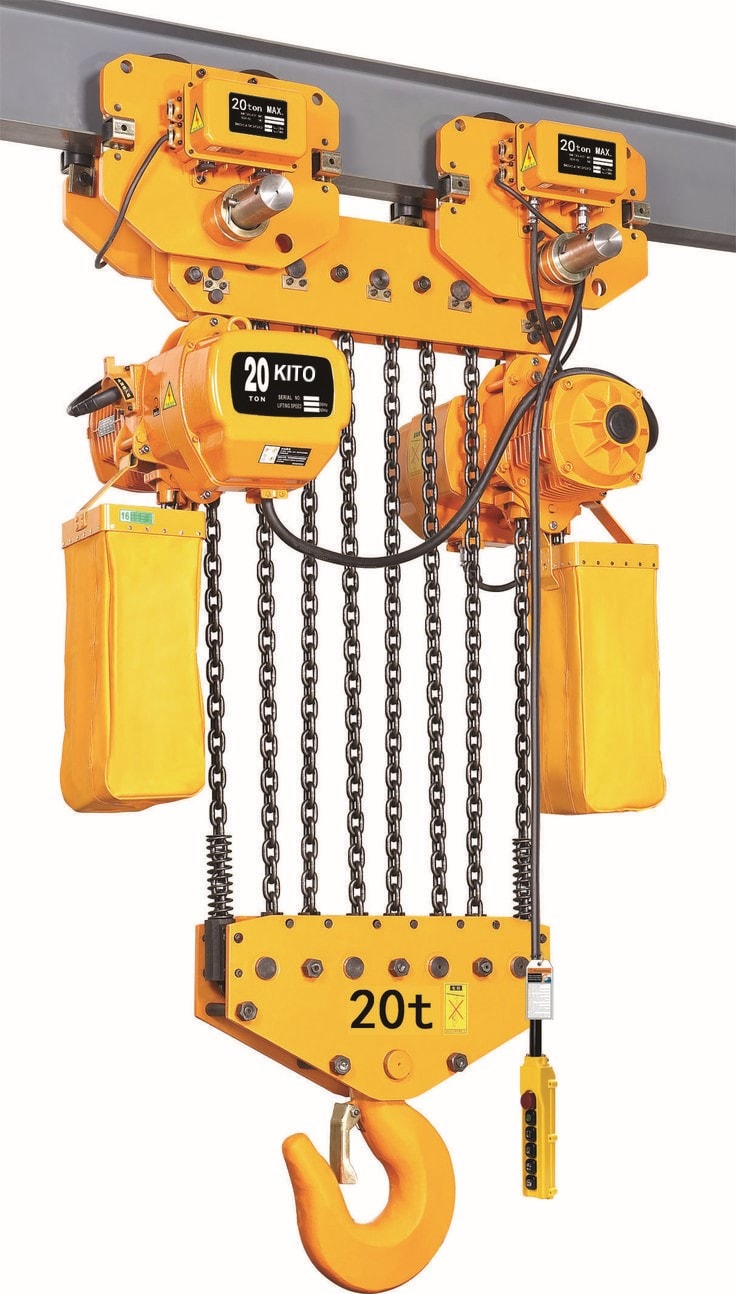

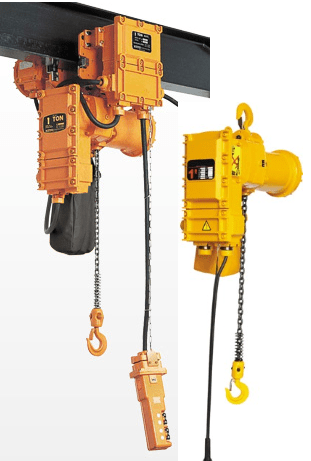

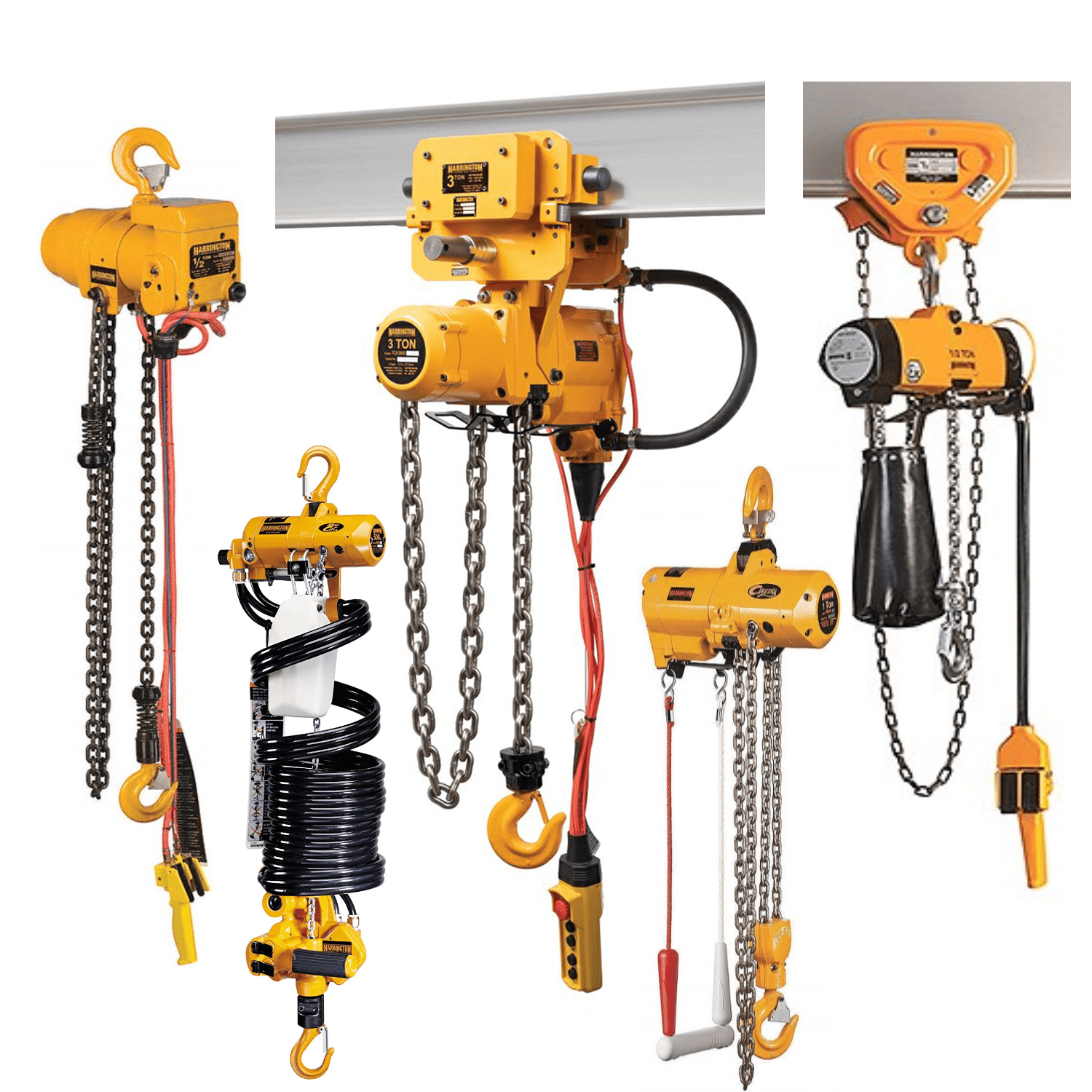

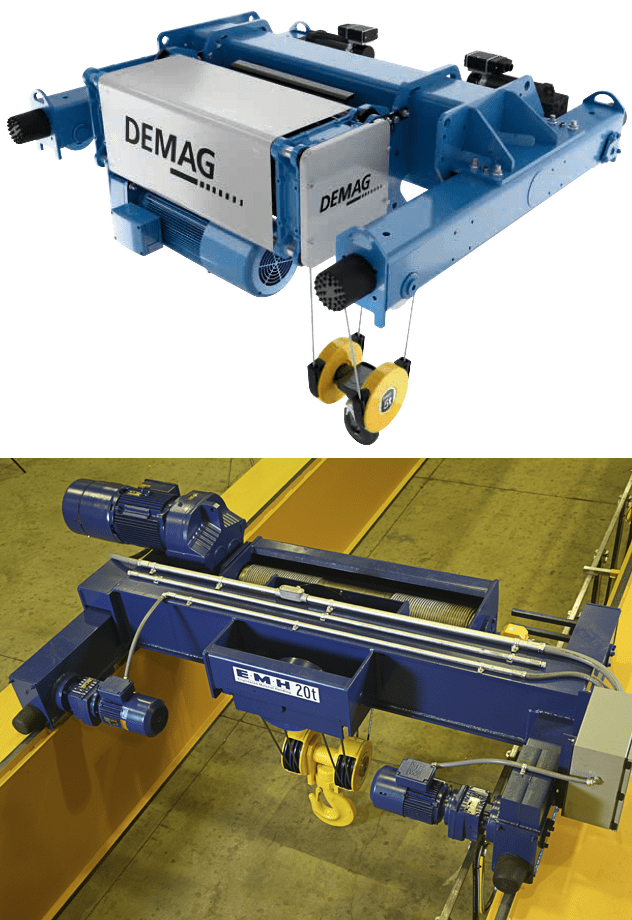

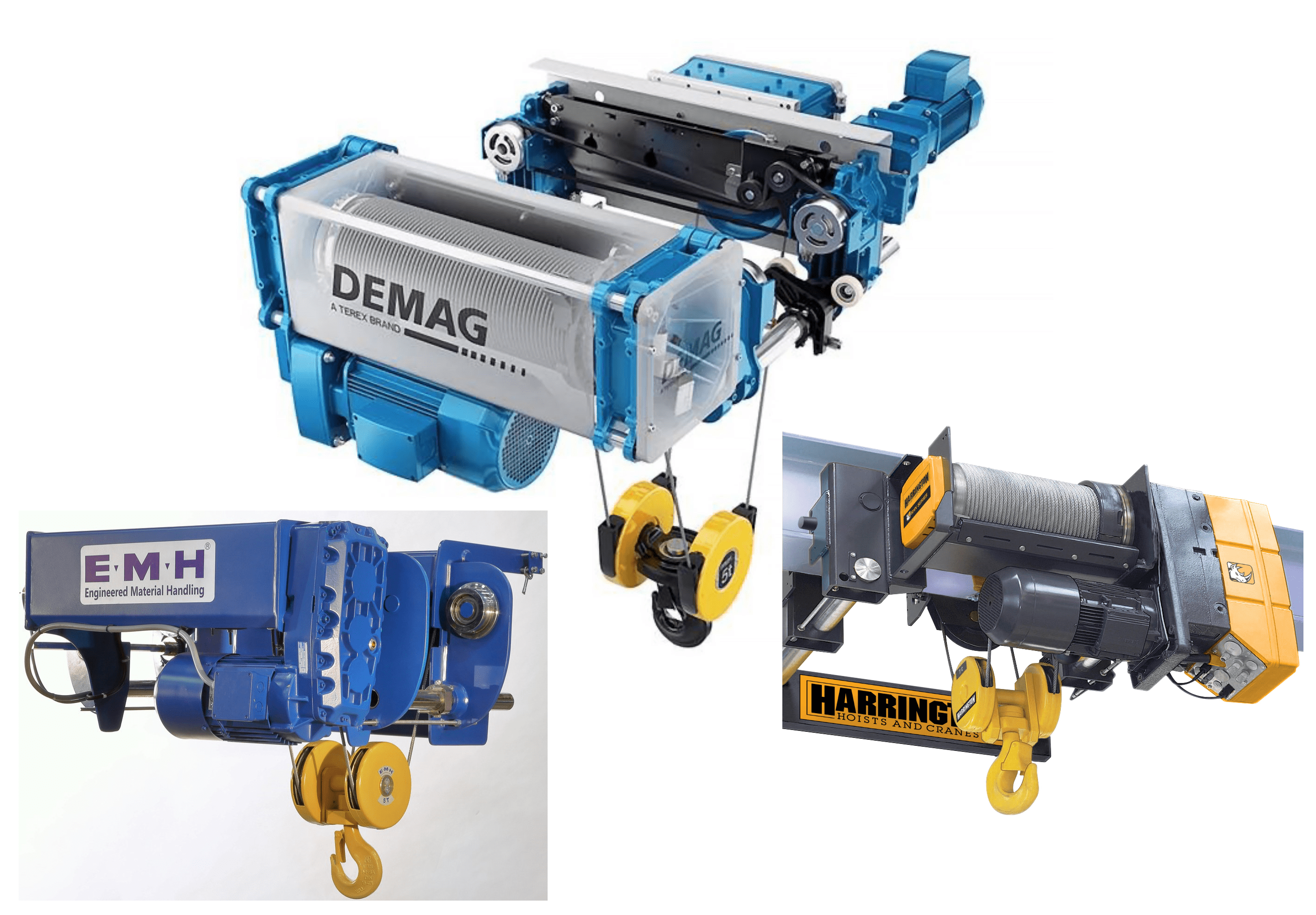

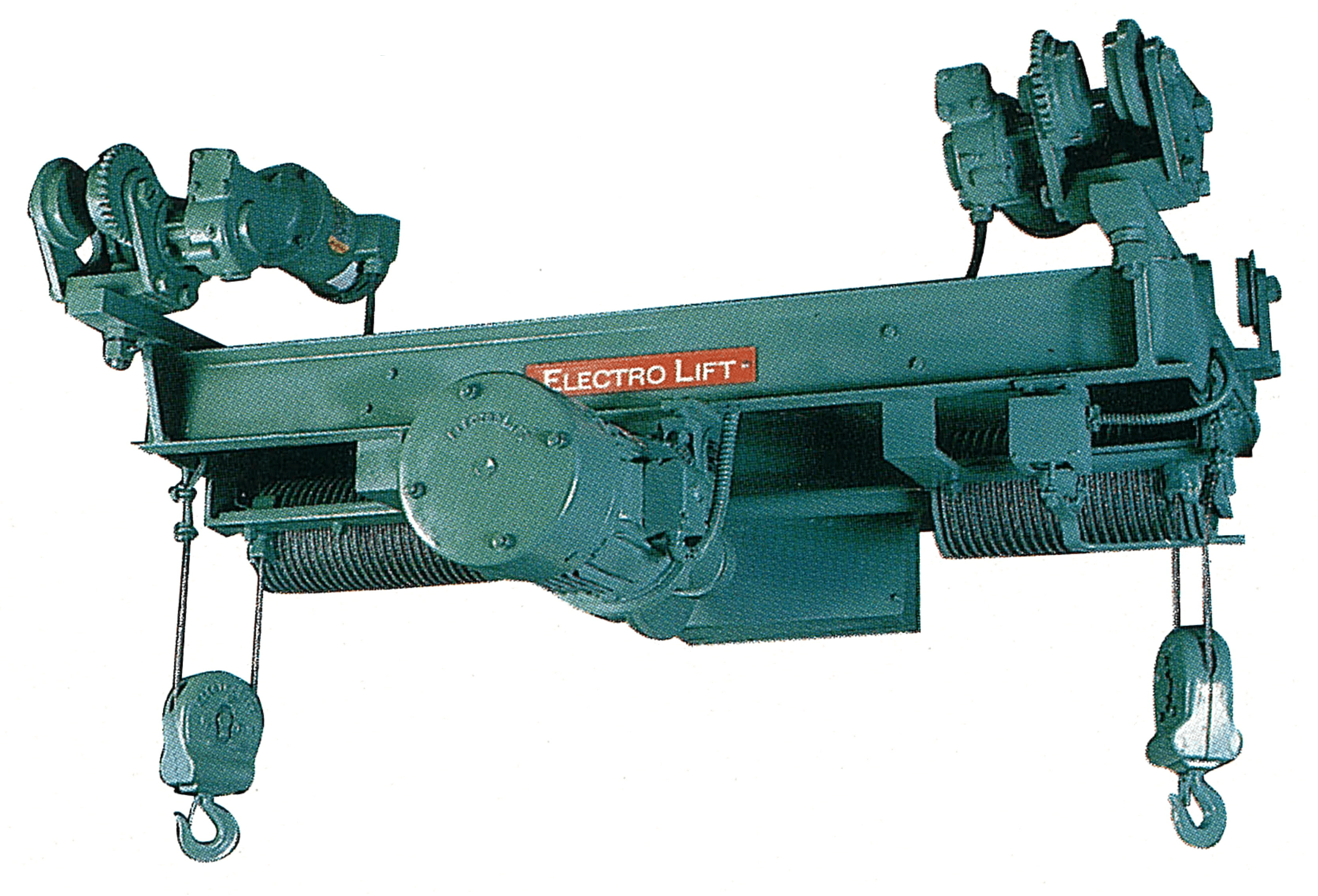

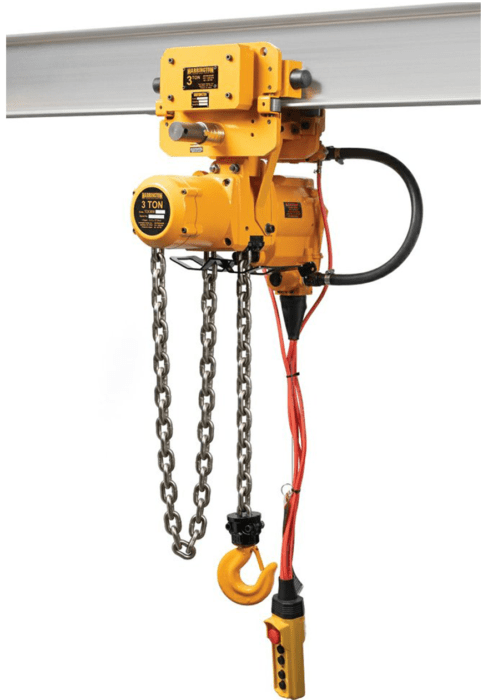

Electric Hoists

Electric hoists are the most commonly utilized. They are powered by an electric motor—controlled by either a pendant or radio system—the motor drives the movement of the chain or wire rope during lifting and lowering operations.

These hoists are available in chain or wire rope variations. Electric chain hoists generally see use in applications involving up to 10-ton loads, while electric wire rope hoists are used for up to and beyond 10-ton load applications.

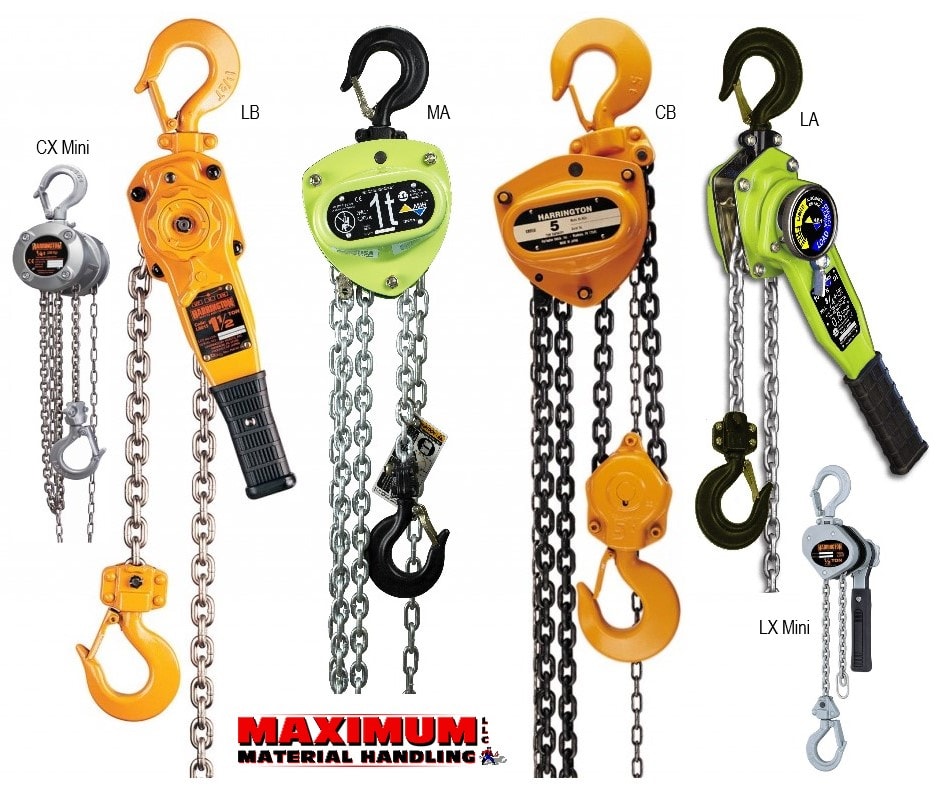

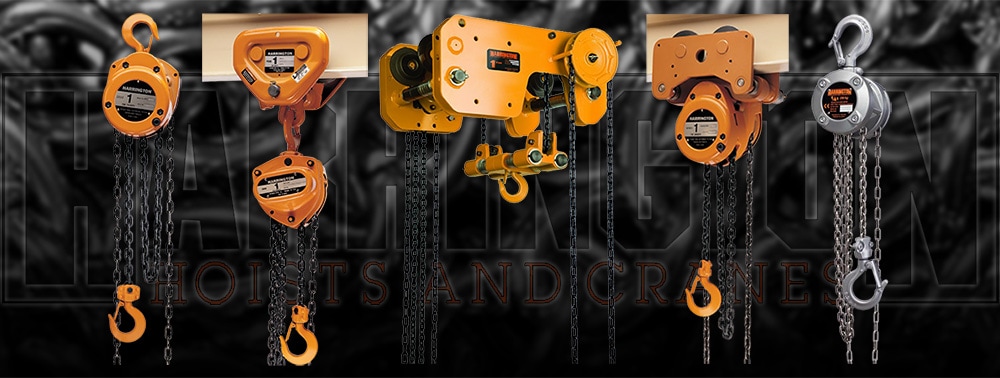

Manual Hoists

Manual hoists do not use any additional power sources to drive the wire rope or chain components. Their simple and compact design makes them well-suited for use as portable lifting and lowering devices. They often find application in short-term and on-site installation and servicing operations.

Manual hoists are available in chain, wire rope and strap. These hoists are commonly referred to as; hand chain hoists, chain blocks, lever hoists, pullers, come-a-longs and tug-its.

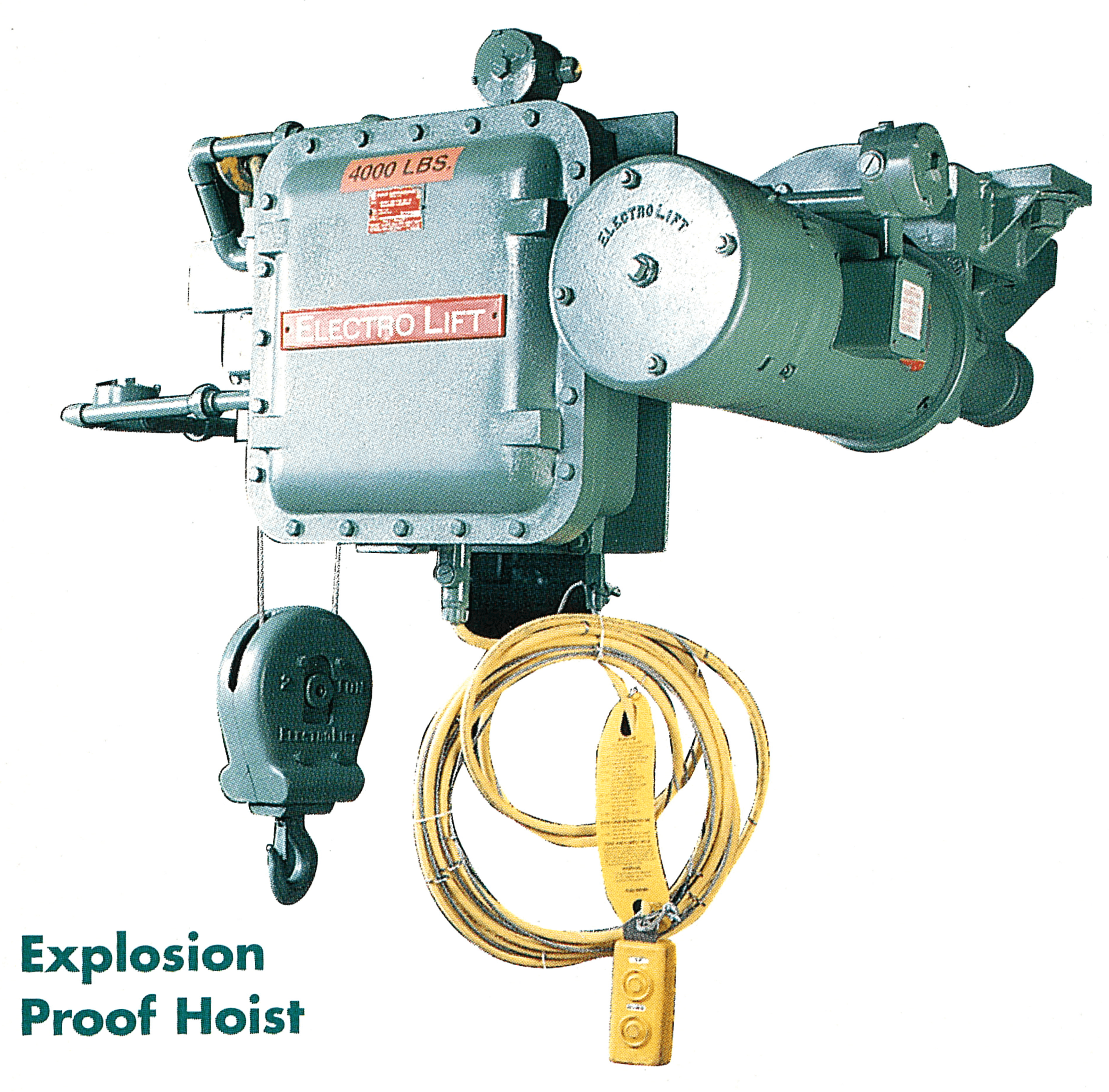

Air/Pneumatic Hoists

Air/pneumatic hoists utilize the force generated by compressed air to raise and lower loads. While they are limited in their load capacities, their spark-resistance and explosion-proof nature make them well-suited for use in hazardous environments.

Typical industrial uses include integration in chemical and food processing operations. They are available in chain or wire rope.

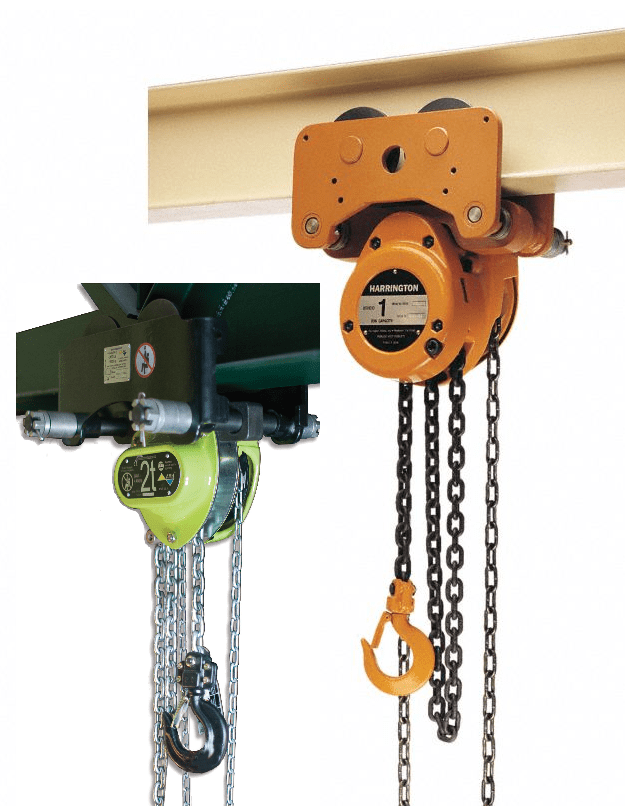

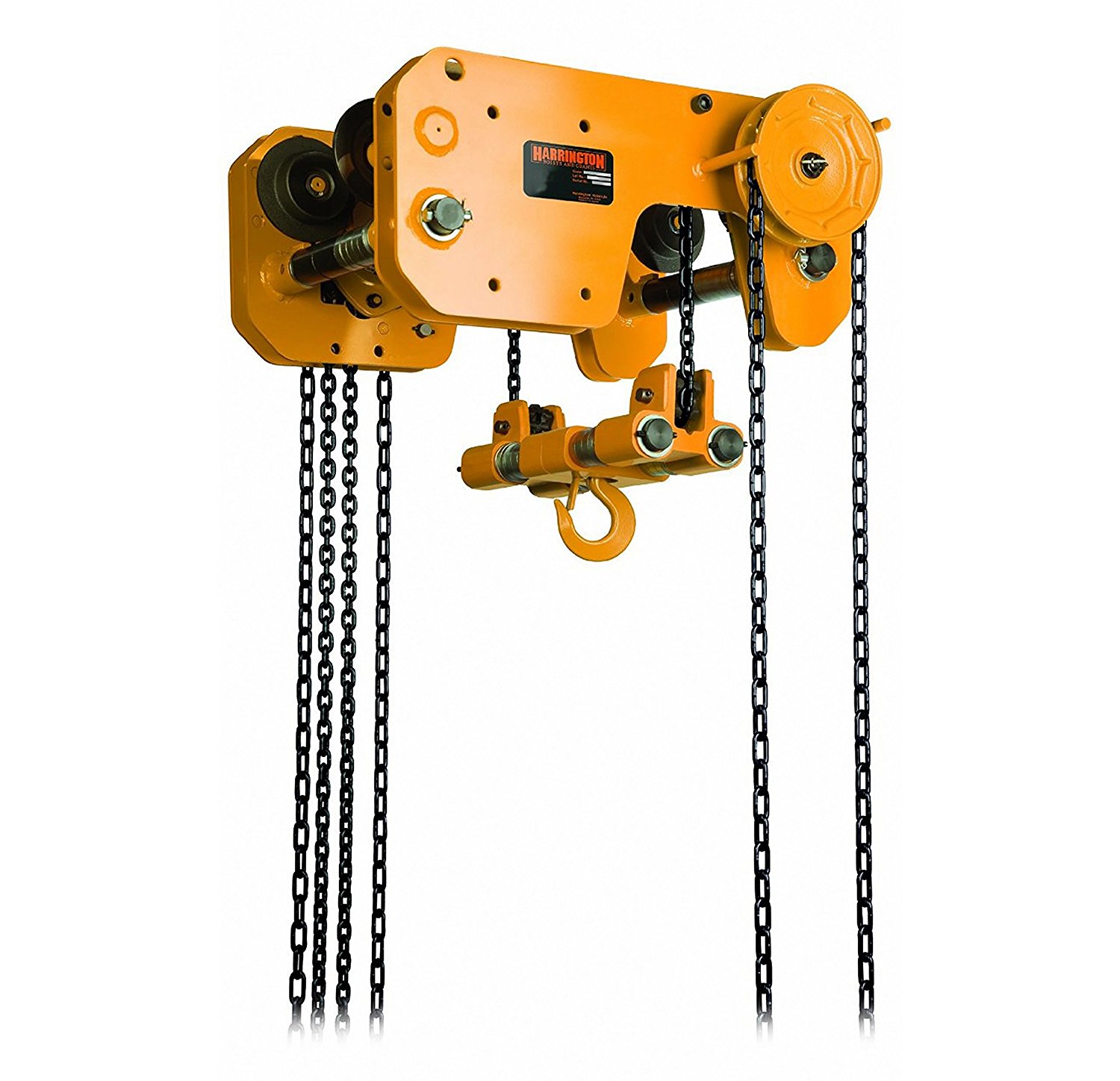

Trolley; definition (noun) (as it relates to material handling)

A wheeled device suspended from and or traveling on an overhead rail or rails, designed to transport a load.

Overview of Trolleys

Similar to hoists, trolleys are available in three main types:

- Electric: uses a motor controlled by a push-button device

- Manual: pushed by the machine operator

- Air/pneumatic: employs an air-powered motor

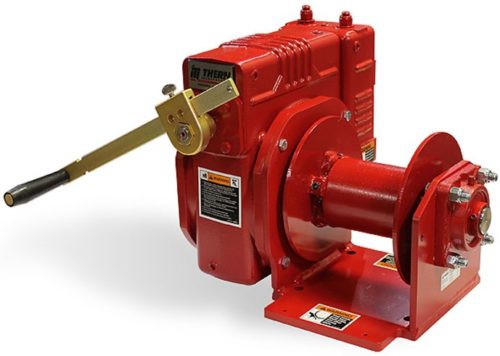

Winch; definition (noun) (as it relates to material handling)

A mechanical advantage device, designed for pulling, hauling or lifting loads, by means of wrapping a rope, wire rope or chain around a rotating drum, driven by a crank, gear or sprocket.

Overview of Winches

Available in manual, air and electric powered formats, winches are extremely versatile and allow the user to establish a wide range of kinetic systems, from simple to complex. When implementing some of the many accessories available, winches provide the user an opportunity to gain mechanical advantage, avoid obstacles, and innovate dynamic solutions in order to meet a diverse set of applications.

Quality Material Handling Solutions From Maximum Material Handling

The majority of hoists and trolleys do not require custom engineering. Instead, they are pre-engineered units assembled in various configurations to suit different lifting/lowering and traveling requirements. For many industry professionals, determining what type of hoist or trolley they need for an application can be a daunting task. Fortunately, the experts at Maximum Material Handling are here to help.

Equipped with years of industry experience, our team has the knowledge to devise and deliver a solution to virtually any material handling need, regardless of lift or load requirement. In addition to providing quality equipment from reputable manufacturers, we offer repair, maintenance, installation, inspection and training services for all of our hoist and trolley products.

For more information on our product and service offerings, contact us today.

Hoist & Trolley Types